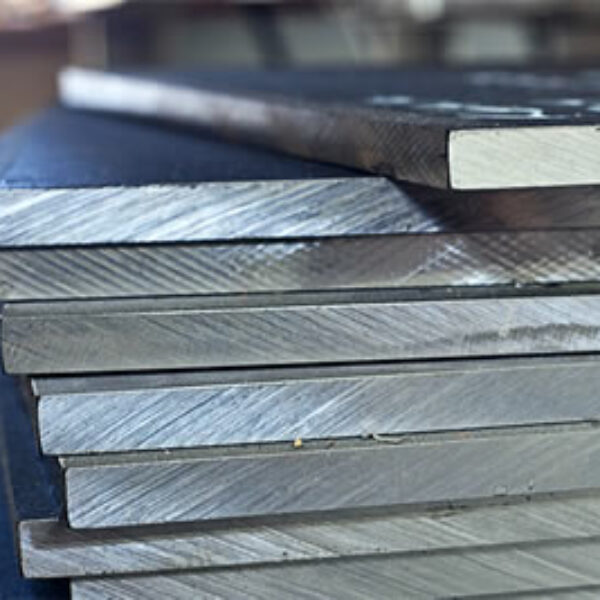

TIASCO services a wide range of industries with quality aluminized steel products:

Aluminized steel is hot-dip coated on both sides with aluminium-silicon alloy. This process assures a tight metallurgical bond between the steel sheet and its aluminium coating, producing a material with a unique combination of properties possessed neither by steel nor by aluminium alone.

Product Feature

CORROSION RESISTANCE

Aluminized Steel has superior performance compared to zinc-coated materials for resistance to atmospheric and salt spray corrosion.

FORMABILITY

Aluminized Steel produces parts containing simple bends to parts with deep drawing requirements.

HEAT REFLECTIVITY

Aluminized Steel Type 1 has excellent heat reflectivity during exposures to temperatures below 800 °F (427 °C), reflecting up to 80% of the radiant heat that impinges upon it.

HIGH-TEMPERATURE PROPERTIES

Aluminized Steel is an excellent heat resistant material effective up to 1250 °F (677 °C). For applications above 800 °F (427 °C) where alloying of the coating is a concern.

Our aluminized steel material selection offers an extensive assortment of shapes, finishes and alloys, which can be cut-to-size for just the amount you need.

Application:

- Furnaces

- Commercial rooftop

- Automotive mufflers

- Gas Burner

- Water heaters

- Fireplaces

- Barbecue burners

- Oven and Baking pans

- Radiators

We offer two types:

- Type 1

- Hot-dip-coated with a thin layer of aluminium/silicon alloy containing 5% to 11% silicon to promote better adherence. The steel can withstand 550 °C (1,022 °F) with almost no change in the base material. However, thanks to silicon content, it develops black spot. Type 1 is also very common in industrial products.

- Type 2

- Hot-dip-coated with commercially pure aluminium. It is principally for applications requiring atmospheric corrosion resistance. Type 2 may ultimately be manufactured into corrugated roofing and siding, grain bins, drying ovens, and air-conditioner condenser housings.

Standard:

- JIS: SA1C, SA1D, SA1E

- EN: DX51D, DX52D, DX53D, DX54D, DX56D

- ASTM: A463 CS, FS, DDS, EDDS

- AS/NZS: 1397

Specification: G1~G3, G250~G450

Base Steel Thickness: 0.43 – 3.56 mm

Width: 20mm~1525mm Length: Up to 12,000mm

Coating Mass: T1 13~60

Feel free to contact our team anytime.