Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.

Due to our stringent production parameters and standard, our laser cutting steels offer considerable advantages and high added value.

TIASCO supplies steel coils, sheets and plates for laser cutting with reduced internal stresses. For our sheets, we offer a guaranteed flatness. They maintain their flatness before, during and after laser cutting.

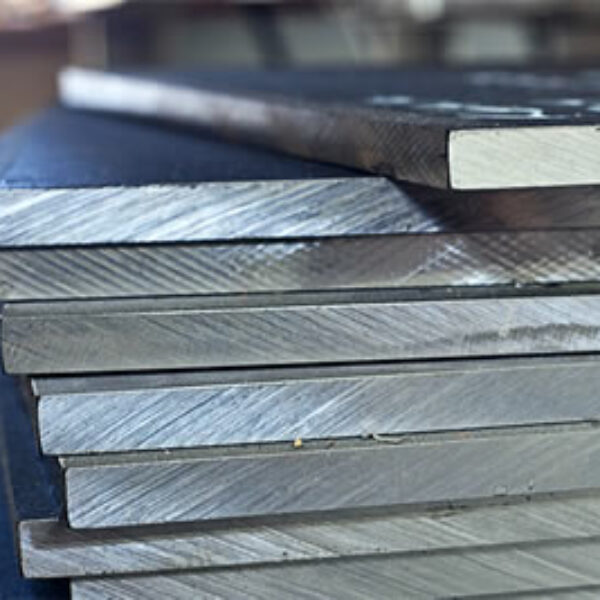

- Significantly higher cutting speed Our plasma steels are suitable for applications where extremely precise cuts, clean and accurate cutting edges and distortion-free parts are required.

- The stable cutting process minimises machine standstills.

- Cut edges exhibit excellent surface quality: they are clean, accurate, and free of burrs.

- Processing performance is consistent due to the narrow tolerances in the mechanical properties, reducing the springback.

- Excellent welding performance.

- Class 1 galvanisability is guaranteed.

- Excellent cold formability.

- Significant cost savings are possible due to lower material costs, improved quality and yield, and the reduction in machine downtime.

Coils, sheets and a choice of finishes

Our laser steel product range includes formable steels for bending and drawing applications, structural steels and High Strength Low Alloy grades.

Mill or pickled finishes are available.