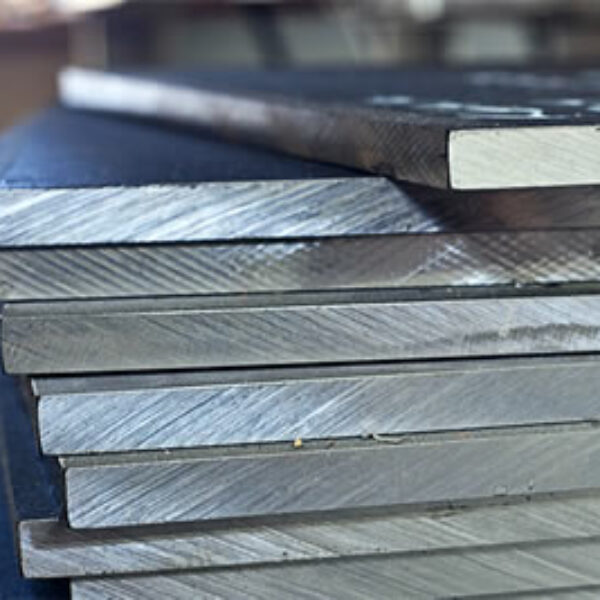

Lyten grade 350 steel plates- a copper chromium alloy steel – this alloy displays a greater level of resistance to atmospheric weathering when compared to other unalloyed steels. Its chemical composition promotes the early formation of an adhering protective layer of rust when exposed to the elements.

Weathering steel, often referred to by the genericized trademark COR-TEN steel, and sometimes written without the hyphen as corten steel, or in Australia branded by Bluescope Lyten is a group of steel alloys which were developed to eliminate the need for painting, and form a stable rust-like appearance after several years’ exposure to weather.

What’s more, it’s also more environmentally-friendly than traditional steel.

The combination of weather resistance and workshop performance makes TIASCO Weathering and COR-TEN® steels a cost-efficient choice for a wide range of applications.

APPLICATIONS

Aesthetically pleasing to the eye, this finish has become popular with many high profile architects and has been specified and used in a variety of applications in including building fascias, architectural sculptures and bridges. Examples of Corten structures include…

- The Angel of the North (UK)

- Matsunoyama Natural Science Museum (Japan)

- The Center for Contemporary Art (Australia)

The protective layer constantly develops and regenerates over time, reacting to the pollutants in the atmosphere. Consideration should be made with regard to the thicknesses used especially when the material is utilised for structural rather than solely cosmetic purposes.

The benefits of such steel are immediately obvious – a self–protecting steel is economical, long-lasting and easily recyclable. TIASCO produces and stocks of Corten–B and Corten–A.

DIMENSION CAPABILITIES

THICKNESS (mm):1.2mm~150mm

WIDTH (mm) : Max 4,500mm

AVAILABLE PROCESS: Dry, pickled and oiled

AVAILABLE FORM: Coil, Strap, Plate, Sheet, Circle, Laser/plasma cut and more.

Corten Grades & Equivalents

The grades and equivalents of Corten steel are provided in the following table.

| Corten | EN 10025-5:2004 |

| Corten A | S355 J0WP |

| Corten B | S355 J0W & S355 J2W |

Mechanical Properties and Thickness Ranges for Corten

The mechanical properties and thickness ranges of Corten steel are provided in the following table.

| Thickness (mm) Strip Products |

Plate Products | Yield strength minimum |

Tensile stength minimum |

Elongation miniumum |

|

| Corten A | 2 – 12 | 6 – 12 | 345 | 485 | 20 |

| Corten B | 2 – 13 | 6 – 40 | 345 | 485 | 19 |

Chemical Composition of Corten Steel

The chemical composition of Corten steel is provided in the following table.

| Content, % (ladle analysis) | ||||||||||

| C (max) |

Si | Mn | P | S (max) |

Al | V | Cu | Cr | Ni (max) |

|

| Corten A | 0.12 | 0.25–0.75 | 0.20–0.50 | 0.07–0.15 | 0.030 | 0.015–0.06 | – | 0.25–0.55 | 0.50–1.25 | 0.65 |

| Corten B | 0.19 | 0.30–0.65 | 0.80–1.25 | 0.035 max. | 0.030 | 0.020–0.06 | 0.02–0.10 | 0.25–0.40 | 0.40–0.65 | 0.40 |