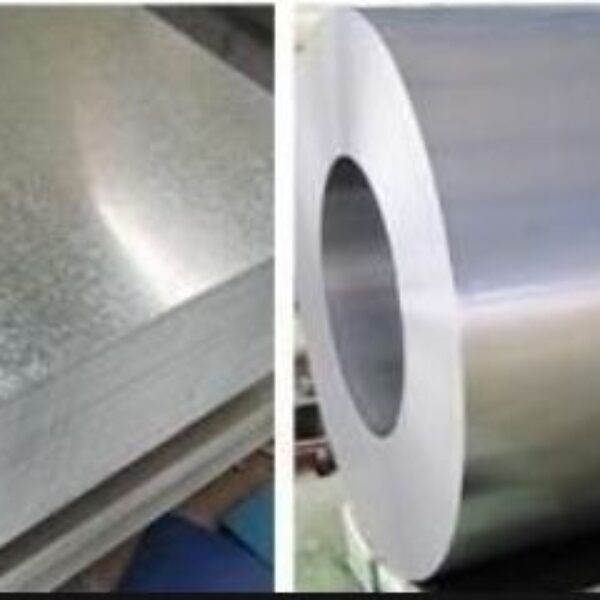

ZAM Steel by TIASCO is a superior corrosion-resistant hot-dip Zinc-Aluminum-Magnesium alloy coated steel sheet. Due to the effects of magnesium and aluminium, ZAM has excellent corrosion resistance, scratch resistance

What does mean by ZAM?

It is a remarkably superior corrosion-resistant hot-dip Zinc-Aluminum-Magnesium alloy coated steel sheet product.

This amazing coated steel product lasts longer in the most severe environments, provides built-in cut edge rust protection, and promotes cost savings through less maintenance.

The Benefits of ZAM Steel Steel

- Longer Product Life: In terms of corrosion resistance, ZAM Steel is 10 to 20 times better than hot-dip zinc-coated steel sheets*1 and 5 to 8 times better than hot-dip zinc-5%aluminum alloy coated steel sheets*2. Excellent corrosion resistance is achieved on the cut edge of ZAM Steel with a fine zinc-based protective film that contains Al and Mg leaching from the coating layer.

- Cost-Effective: ZAM Steel can contribute to reducing costs significantly – for instance, it enables initial cost reduction through process omission and life cycle cost reduction thanks to its superior corrosion resistance.

- Suitable for severe environments

- Aluminium, zinc and magnesium material elements combine to form a protective barrier on the coating surface over time

- Provides additional protection for Purlins and Condeck

- Replaces the need for higher coating weights

- Provides raw edge protection and is concrete compatible and scratch-resistant

- Can replace stainless steel and aluminium in some application

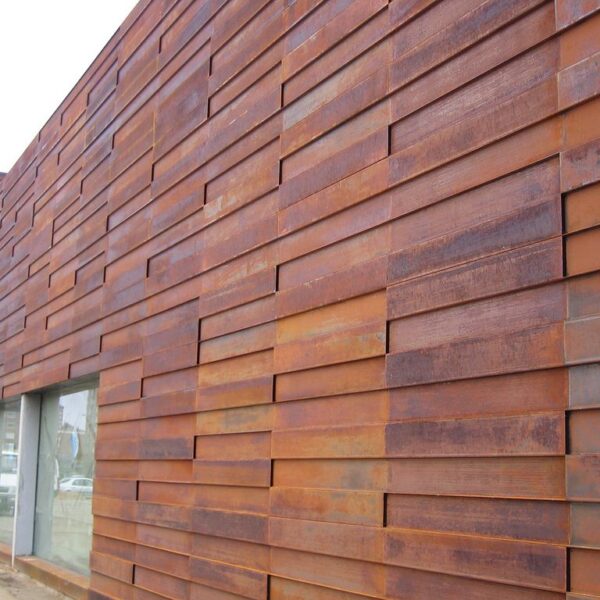

ZAM Steel Applications

Suitable applications for ZAM include: construction (architectural building panels, perforated panels, metal facades, roofing), automotive, agricultural applications (chicken grow outhouses, swine containment, hoop buildings, grain bins, silos, etc.), greenhouse structures, industrial HVAC, cooling towers, solar racking, school bus decking, swimming pool, signposts, guardrail facades, coastal environments, cable trays, switch boxes, steel decking and framing, sound/wind/snow barriers and many other applications.

The finished product always has a brighter and shiner surface finish than the hot-dipped version. The sheet’s surface weldability is especially better for spot and seam welds.

TIASCO Steel can offer you a strong and durable ZAM Steel product, appropriately suited to your construction or manufacturing projects.

ZAM Steel Specifications

| MATERIAL THICKNESS | 0.3mm through 5mm | |||||||||

| MATERIAL WIDTH | 400mm~1500mm | |||||||||

| ASTM SPECIFICATION | ASTM A1046/A1046M Type 1 AS/NZS 1397 |

|||||||||

| STEEL GRADES |

|

|||||||||

| COATING WEIGHT |

(Please inquire about any coating weights not listed.)

|

|||||||||

| COIL WEIGHT | 10,000 lbs. maximum through 55,000 lbs. maximum | |||||||||

| COIL ID | 20″ and 24″ | |||||||||

| AFTER TREATMENT (upon request) |

Chemical Treatment (RoHS Compliant Available) Oiling Acrylic (RoHS Compliant, Please Inquire) Stenciling |